SeaPort-e is the Navy’s electronic platform for acquiring support services in 22 functional areas including Engineering, Financial Management, and Program Management. The Navy Systems Commands (NAVSEA, NAVAIR, SPAWAR, NAVFAC, and NAVSUP), the Office of Naval Research, the United States Marine Corps, and the Defense Threat Reduction Agency (DTRA) use this vehicle to contract for their service requirements.

Sea PORT

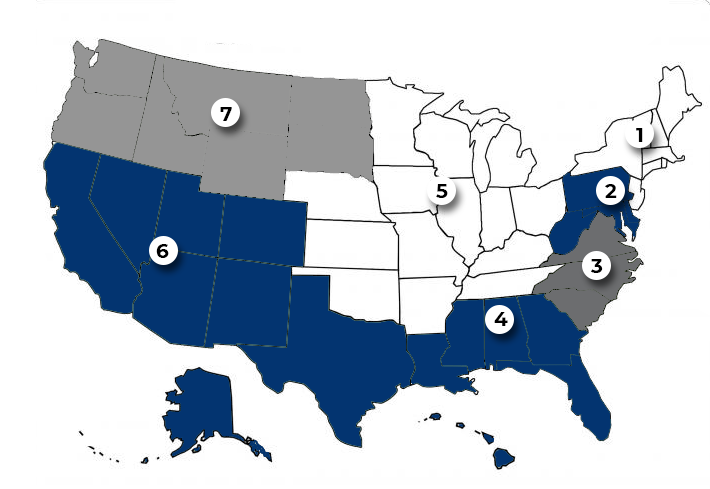

SGS is qualified as a Prime Contractor to support major functional areas in geographic zone–4 as defined by the contract.

- Zone 1 - Northeast Zone

- Zone 2 - National Capital Zone

- Zone 3 - Mid-Atlantic Zone

- Zone 4 - Gulf Coast Zone

- Zone 5 - Midwest Zone

- Zone 6 - Southwest Zone

- Zone 7 - Northwest Zone

Anand Venkatesan (904)332-4534

6817, Southpoint Parkway, Jacksonville, FL-32216

The foundation of our staffing and management plan includes:

- Cumulative experience and expertise

- Due diligence regarding all processes involved

- Iterative quality checks

- Effective feedback mechanisms

- Swift and effective resolution of issues

- Complete adherence to industry best practices

SGS Technologie leverages proven and effective cost saving processes. A majority of the sub-processes have been developed by our in-house team as a direct result of our experience and exposure to different clients, technologies, project-requirements, frameworks et al. over the 16+ years in operation.

Monitoring and Controlling:

- Measuring the ongoing project activities (where we are);

- Monitoring the project variables (cost, effort, scope, etc.) against the project management plan and the project performance baseline (where we should be);

- Identifying corrective actions to address issues and risks properly (i.e. How to get back on track)

- Effective feedback mechanisms

- Swift and effective resolution of issues

- Complete adherence to industry best practices

Closing Process:

The SGS closing process includes the formal acceptance of the completed project. All activities and document lessons learned are archived. This phase consists of:

- Finalize all activities across all of the process groups to formally close the project or a project phase

- Contract Closure: Complete and settle each contract (including the resolution of any open items) and close each contract applicable to the project or project phase

Process Control Modalities:

- Anticipated Feed Forward –Proactive measurement, analysis, and implementation. This modality is essentially a buffer induction in anticipation of probable and possible issues.

- Concurrent and Ongoing –Our highly agile and responsive issue detection and redressal mechanisms form another integral part of the defenses. The ongoing processes have probable errors that will be dealt with in real-time.

- Feedback and Response –We consistently examine the processes and the consequent documentation to ascertain whether any intervention is required. This is also a part of the defense that is active after an issue has occurred

SGS Technologie is follows rigorous adherence to quality standards, and its management. SGS develops customer driven strategies that are primed for identification, translation, and incorporation of quality feedback into the ongoing processes.

SGS follows the ISO 9001 standard advocated “Process Approach”. We base our operations on well-defined, structured, and quality optimized process cycles. We have:-

- An organization specific “Quality Policy”

- Establish process parameters

- Thorough documentation

- Clearly demarcated roles and responsibilities

- Rigorous implementation, monitoring, and measurement of established parameters

- Management reviews

ISO Quality Management Methodology: SGS follows a customized Quality Control process drawing the best features of the Six Sigma Methodology and the PDCA (Plan-Do-Act-Check) Cycle.

- Plan/Define:Identify possible/present problem, define the goals, and clarify the scope

- Do/Measure:Performance metrics are gathered

- Check/Analyze:Information analyzed, best practices adopted, and requirements refined

- Improve:Incorporate feedback, implement reviewed and approved changes

- Act/Control:The maintenance cycle is developed and implemented

Service Gaps

The SGS approach maintains a constant vigil to detect and identify service gaps. We make certain that customer requirements are fully understood and provide realistic time frames after due diligence by the service staff. The continual and effective communication between the customer and the development team generates invaluable feedback and input. SGS will maintain a high quality of communication and mitigate the possibility of any future gaps.

The most recent conformed copy of each Task Order received under this contract.

No orders received yet.